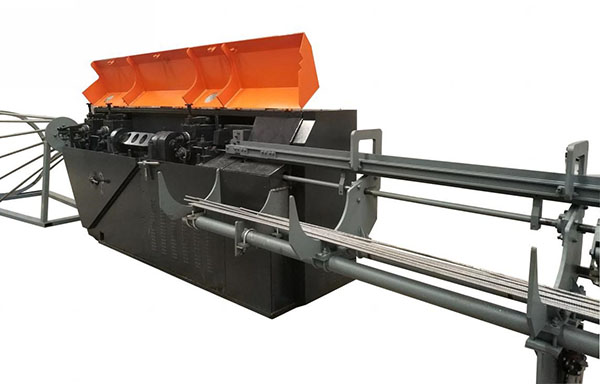

HIGH SPEED STRAIGHTENING & CUTTING MACHINE use the high speed rotating spinner to make straightening. This machine make straight bar from coil in high efficiency.

| material characteristics | Model No. | |||

| KZT3-1DX | KZT5-12X | KZT8-14TX | KZT12-16X | |

| Hot rolled smooth surface coiL | φ3 -φ10 | φ5-φ12 | φ8-φ14 | φ12-φ16 |

| Hot rolled ribbed coilyieLd Strength 335Mpa | φ3 -φ8 | φ5-φ12 | φ8-φ14 | φ12-φ16 |

| Hot rolted ribbed coilyieLd strength 4Q0Mpa | φ3 -φ8 | φ5-φ12 | φ8-φ14 | φ12-φ16 |

| Cold rolled coil | φ3 -φ10 | φ5-φ12 | φ8-φ14 | φ12-φ16 |

| Cut-to-length (m) | 1-12 | |||

| Straightening speed (m/min) | 70-100-130 | |||

| straightness accuracy (mm/m) | 2 | |||

| Cold rolled coil (mm) | ≤±1 | |||

| Cold rolled coil (kw) | 18.5+7.5 | 22+7.5 | 37+7.5 | 45+7.5 |

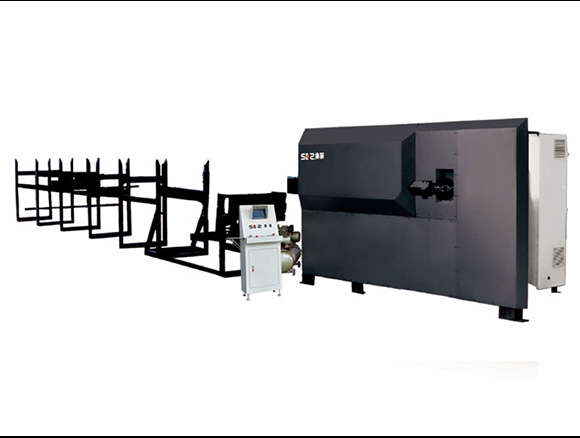

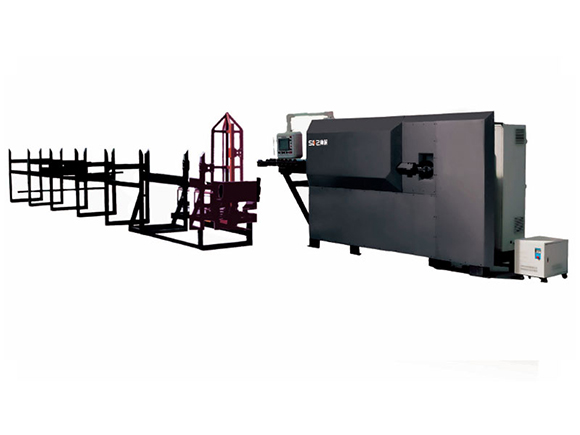

STRAIGHTENING & CUTTING MACHINE PRINCIPLE

1..CENTRAL MACHINE

2.WIRE PAYOFF

- Maximum carrying capacity 2,000Kg.

Equipped with wire guide and safety funnel

Equipped with 1set of vertical payoff and 1set of guide funnel

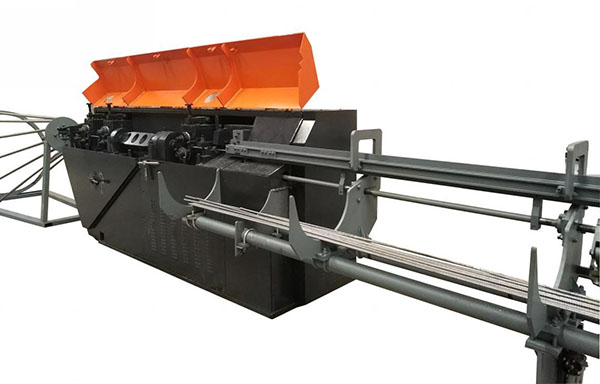

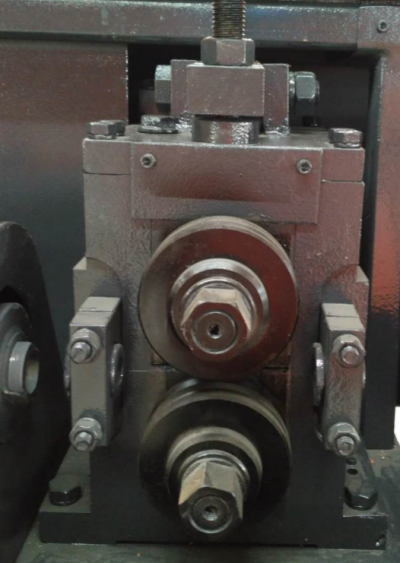

3. WIRE INLET FEED UNIT

3. WIRE INLET FEED UNIT - Two independent incoming towing devices.

Each device is made up of two pulleys whose aim is to feed the wire toward to the rotating unit.

The pulley is equipped with two races whose profile depends on the shape and dimensions of the wire to be processed.

The upper pulley pressure is adjusted by screw and pneumatic clamping.

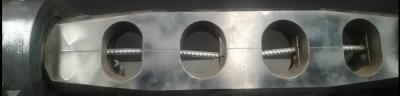

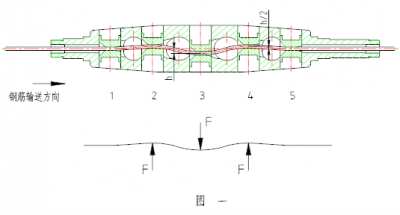

4.STRAIGHTENING ROTATING BODY

- The most important component of the machine.

There are five couples of dies inside the body. The machine is normally supplied with two types dies (standard cast-iron dies) for the process of the small and large wires.

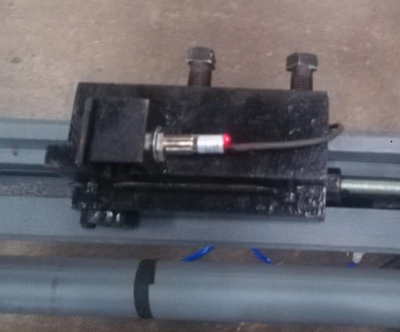

5.WIRE OUTLET FEED UNIT

- Out-feed unit is made up of two pulleys whose aim is to drag the wire from the rotating unit to the cutting unit.

- The pulley is equipped with two races whose profile depends on the shape and dimensions of the wire to be processed.

- The upper pulley pressure is adjusted by screw and pneumatic clamping.

- The cut unit is made up of an arm within which there is cutting knife, moved by an independent servo-motor operating on a can cutting the wire to the required length.

6.CUTTING UNIT& COLLECTING BENCH

- 12m collecting bench with preselecting rod counter (buffering device) and collecting pocket.

- The cutting control device (length measuring) is mounted in the frame. Any required length between 1,000-12,000mm can be setup manually.

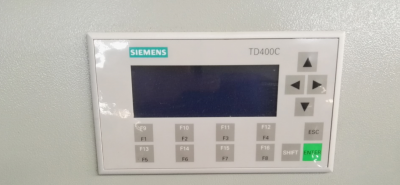

7.ELECTRIC CABINET AND CONTROL CONSOLE

- Siemens electric cabinet

Button and touchable screen coordinated operation system

CN

CN